Complete Guide to Making Your Own Network RJ45 Connectors: Essential Skill for Security System Professionals

-

-

Author: Tony

-

37

- Wx Share

-

-

From stripping to crimping: The complete manufacturing process of a network RJ45 connector

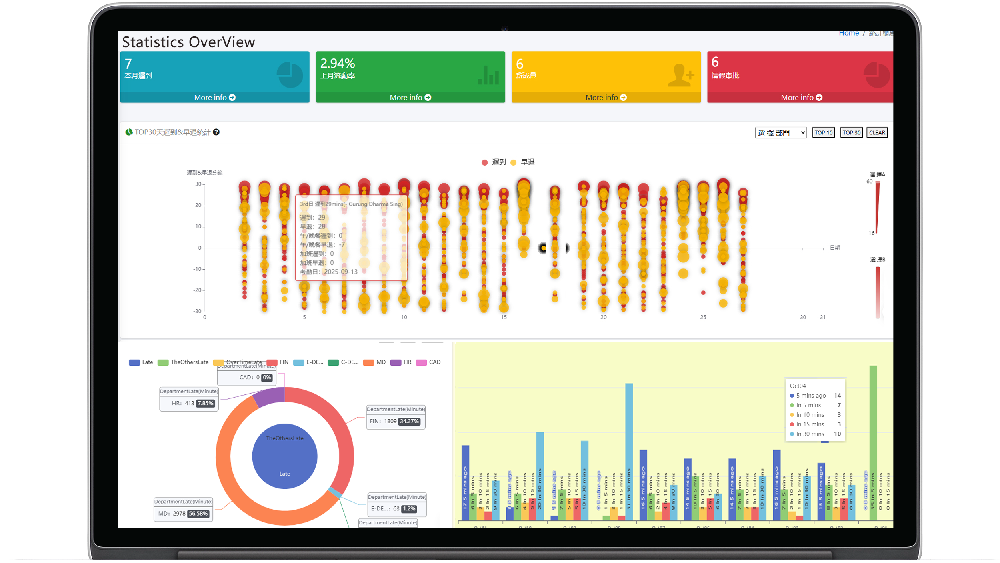

Time & Payroll Suite

Attendance, Payroll and Access Control Solution for Cost Reduction and Productivity Gains Details

All‑in‑one automated timekeeping and payroll system with robust, secure processes to guarantee payroll integrity. Includes leave management, shift rostering, multi‑site and chain support, multi‑ledger accounting, and comprehensive modules.

Why Network Maintenance Professionals Need to Learn How to Make RJ45 Connectors?

For network maintenance professionals, mastering how to make network RJ45 connectors is a highly valuable skill. Compared to pre-made network cables, self-made cables not only allow flexible length control and cost savings but also enable the selection of high-quality materials based on actual needs, ensuring network transmission quality. In the security industry, this skill is particularly important because security systems such as CCTV systems, access control systems, burglar alarm systems, video surveillance systems, remote monitoring systems, parking management systems, intercom systems, and patrol systems all require reliable network connections to ensure proper operation.

Tools and Materials Preparation

Before starting to make RJ45 connectors, you need to prepare the following tools and materials:

- RJ45 connectors: It is recommended to choose high-quality connectors to ensure stable connections.

- Network cable (Cat5e, Cat6, or higher specifications): Choose the appropriate network cable based on your needs. For example, for intelligent security systems, it is recommended to use Cat6 or higher specifications to support high-speed data transmission.

- Wire stripper: Used to strip the outer jacket of the network cable.

- Crimping tool: Used to crimp the connector onto the network cable.

- Network cable tester: Used to test whether the self-made cable is functioning properly.

Steps for RJ45 Connector Wiring

Step 1: Strip the Outer Jacket

Use a wire stripper to strip about 2-3 cm of the outer jacket from the network cable, being careful not to damage the internal wire cores.

Step 2: Arrange the Wire Order

Arrange the 8 internal wire cores according to the T568B standard. The T568B standard wire order is: orange-white, orange, green-white, blue, blue-white, green, brown-white, brown. This is currently the most commonly used standard and is suitable for the installation of most security systems.

Step 3: Trim the Wire Cores

Trim the arranged wire cores neatly, ensuring they are of consistent length, about 1-1.5 cm.

Step 4: Insert into the Connector

Insert the trimmed wire cores into the RJ45 connector, ensuring each wire core reaches the top of the connector and that the outer jacket also enters the connector interior to increase strength.

Step 5: Crimp the Connector

Use a crimping tool to firmly crimp the connector, ensuring the wire cores are in tight contact with the metal contacts of the connector.

Step 6: Test the Cable

Use a network cable tester to test the self-made cable, ensuring all wire cores are properly connected without short circuits or open circuits.

Common Issues and Solutions

- Incorrect wire order: If the network cable tester shows an error, it may be due to incorrect wire arrangement. Recheck the wire order and remake it according to the T568B standard.

- Wire cores not reaching the top: If the wire cores do not reach the top of the connector, it may cause poor contact. Retrim the wire cores and ensure they are inserted properly.

- Outer jacket not entering the connector: If the outer jacket does not enter the connector, the cable is prone to breakage at the connection point. Ensure the outer jacket also enters the connector interior when inserting the wire cores.

Applications in the Security Industry

After learning how to make RJ45 connectors, you can more flexibly handle the installation needs of various security systems. For example, when installing CCTV systems, you can self-make network cables of appropriate lengths based on camera positions, avoiding waste from overly long pre-made cables. In the installation of access control systems or intercom systems, self-made cables can ensure stable connections and improve system reliability. For remote monitoring systems, high-quality self-made cables can ensure smooth video data transmission, avoiding delays or interruptions.

Conclusion

Making network RJ45 connectors is a simple yet practical skill, especially for network maintenance professionals and security industry practitioners, as it improves work efficiency and ensures system stability. Through the step-by-step explanation in this article, you should now have mastered the correct wiring method for RJ45 connectors. You can now break free from reliance on pre-made network cables and easily handle various network cable usage scenarios, whether for intelligent security systems or traditional burglar alarm systems.

Software Service

Industry information

- Views 8944

- Author :Tony

- Views 603

- Author :Tony

- Views 1661

- Author :Bruce Lee

- Views 41

- Author :Tony

- Views 15

- Author :Bruce Lee

- Views 29

- Author :Tony

Hardware & Software Support

We are deeply rooted in Hong Kong’s local services, specializing in hardware and software issues.

System Integration

Hardware and software system integration to enhance stability and reliability.

Technical Support

Professional technical team providing support.

Professional Technical Services

Focused on solving problems with cutting‑edge technologies.